SUNPOLY™ POLYMER BLANK FACTORY IN GUANGZHOU, GUANGDONG

Started from 2004, we are among the first to manufacture sublimatable polymer blanks in China. The polymer injection factory is set in Guangzhou, a business and manufacturing hub, and the very same city our headquarter locate. With decades of experiences and accumulation, we develop the plant into a highly established line, gathered abundant machine capitals with our high-speed injection line, and an expert working team of engineering, programming, and machine operating. It’s a sturdy base supporting SUNPOLY™ to give stable, competitive, and always-up-to-standard supplies.

POLYMER PRODUCTION: THE PROCESS OF INJECTION MOLDING

The production of polymer items involve two critical lines -- designing & crafting a product mold, and injecting materials to shape and mold the final product. And in order to ensure problem-free imprint for a polymer blank, manufacturing requires high level consistency. Every decision in the link has to be accurately made, and more importantly, made with professional sublimation experiences.

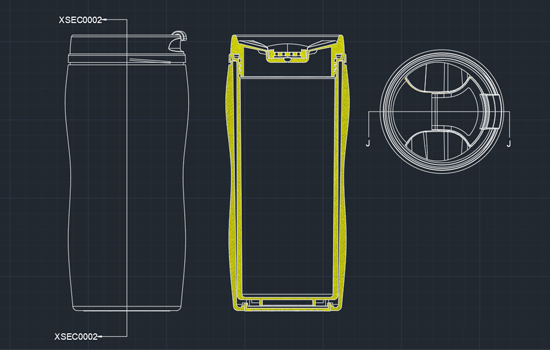

- PRODUCT MOLD DESIGN

|

In polymer manufacture, mold is the machine part where the product is shaped and come into form. Thus, mold design is the most decisive element influencing how your blank is prototyped, and how they successfully get through mass production. Whenit comes to molding for sublimation, the process becomes even more tricky, as the engineer will have to be with special sublimation experiences to control a complex set of model factors in order to ensure final printability. |

|

|

| PRECISE SHAPING | PRODUCT SHRINKAGE CONTROL | |

| When we are designing a mold -- the component that initially decide the shape of your product -- it’s crucial to know whether it will produce a precise final output, including the exact size, surface level, smoothness, shape consistency, etc. Beyond professional technician engineering, calculation has to begin from reasoning a model design that delivers problem-free sublimation. These all require incredible control on every product detail, with both rich knowledge in polymer molding, and shrewd insight for the sublimation industry. | A qualified blank mold should not only project printable shape, but also adjust the final product for true imprint environment. Polymer shrinks to some extent in certain temperature, which is normal in regular polymer production, but imposes vital impact on sublimation blanks, as shrinkage could lead to size deviation, even cracks during transfer. In professional blank producing, we apply strict shrinkage control, with respect to exact final blank size and the imprint solution it needs to fit in. | |

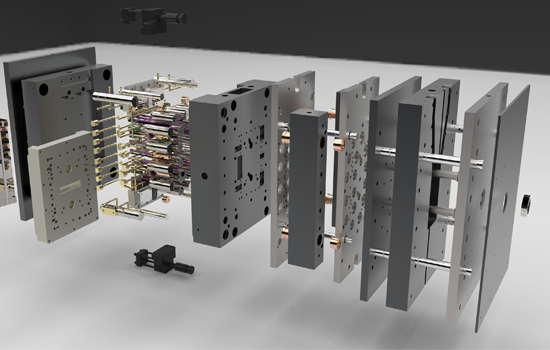

| MOLD FOR PRODUCTION |  |

|

| Another critical qualification for a mold is to be supportive in mass production. While creating sublimation blanks can be particularly demanding in shapes, the mold designed and engineered should also be able to prevent unreasonable default that could lead to inefficient or even failed production. And for turning some novel designs into practical production, our talented mold makers are always with reliable and creative skills to tackle problems and bring about a unique solution. | ||

|

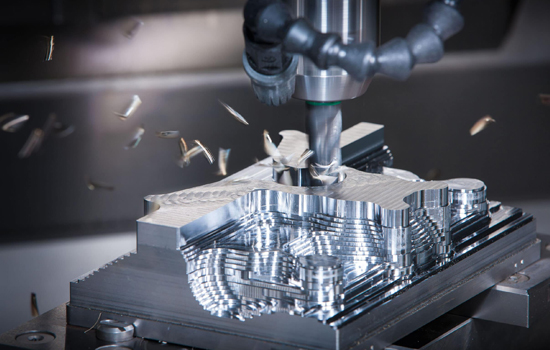

CNC MOLD MAKING | |

| With sound designs and plans, the mold is produced with CNC machine, a digital mechanism that finishes creating a mold in completely automatic digital operation. With years of production, we’re with advanced machine resources, and a skillful team well-trained toprogram and run the project with high efficiency and accuracy. | ||

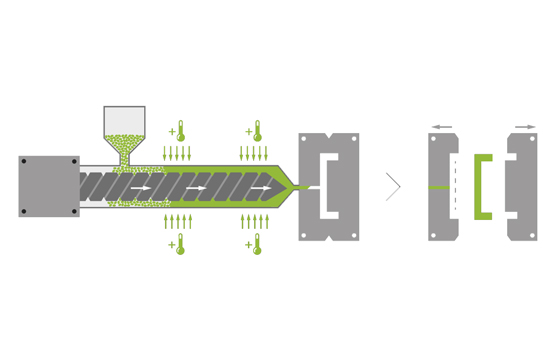

- INJECTION MANUFACTURING

|

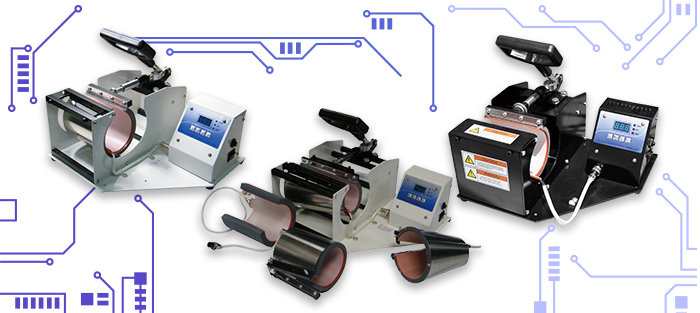

The injection technology applied in manufacturing polymer articles is a super clever production system to bring high consistency and productivity. As polymer being injected and shaped in the mold component, the whole process is automatic with digital program and robotic power, and production is efficiently and accurately repeatable. But meanwhile, everything is based on very skillful manual power to develop intricate formula and program systems. Calculation should involve prediction of material shrinkage, viscosity, flowability, leading to corresponding injection time, temperature, pressures – all demand rigorous manipulation from expert experiences and know-how. |

|

|

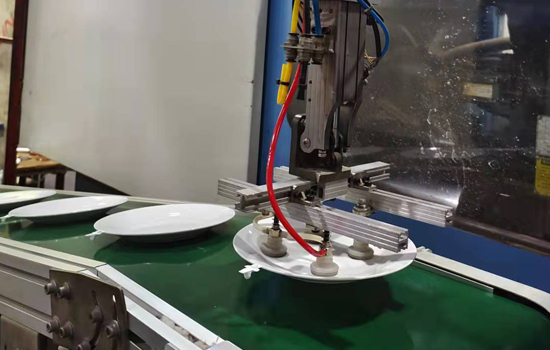

AUTOMATIC OPERATION | |

| Equipped with advanced injection system and facilities, SUNPOLY™ factory provides quality and quick in-time polymer blank molding. We've got heavy robot-arm to move around molds, and the one-step polymer injection machines that automaticallycomplete the whole operation from injection, molding, product demolding, and out-put belt convey. The process is highly productive and labor-saving, and at the same time reliable with low defect rate. | |

|

|