DESIGN FOR PRINTABILITY

In polymer manufacture, mold is the machine part where the product is shaped and come into form. Thus, mold design is the most decisive element influencing how your blank is prototyped, and how they successfully get through mass production. When it comes to molding for sublimation, the process becomes even more tricky, as the engineer will have to be with special sublimation experiences to control a complex set of model factors in order to ensure final printability.

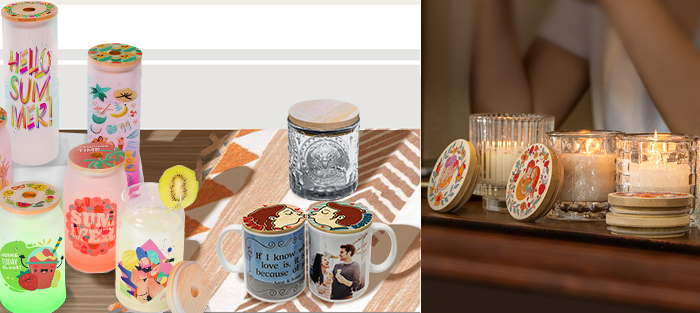

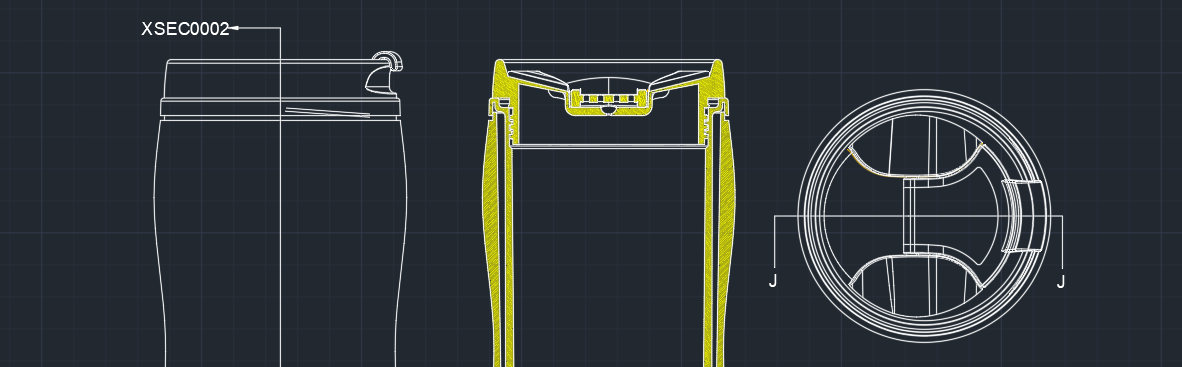

PRECISE SHAPING

When we are designing a mold - the component that initially decide the shape of your product - it's crucial to know whether it will produce a precise final output, including the exact size, surface level, smoothness, shape consistency, etc. Beyond professional technician engineering, calculation has to begin from reasoning a model design that delivers problem-free sublimation. These all require incredible control on every product detail, with both rich knowledge in polymer molding, and shrewd insight for the sublimation industry.

PRODUCT SHRINKAGE CONTROL

A qualified blank mold should not only project printable shape, but also adjust the final product for true imprint environment. Polymer shrinks to some extent in certain temperature, which is normal in regular polymer production, but imposes vital impact on sublimation blanks, as shrinkage could lead to size deviation, even cracks during transfer. In professional blank producing, we apply strict shrinkage control, with respect to exact final blank size and the imprint solution it needs to fit in.

MOLD FOR PRODUCTION

Another critical qualification for a mold is to be supportive in mass production. While creating sublimation blanks can be particularly demanding in shapes, the mold designed and engineered should also be able to prevent unreasonable default that could lead to inefficient or even failed production. And for turning some novel designs into practical production, our talented mold makers are always with reliable and creative skills to tackle problems and bring about a unique solution.

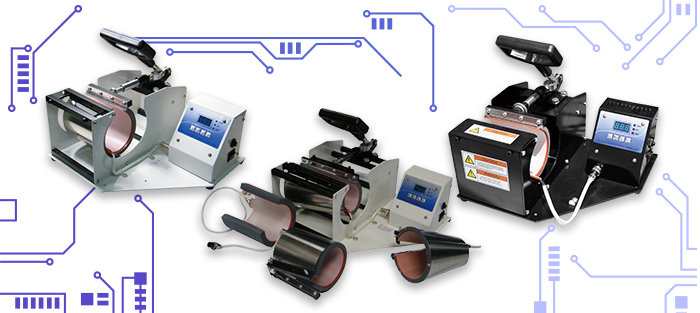

CNC MOLD MAKING

With sound designs and plans, the mold is produced with CNC machine, a digital mechanism that finishes creating a mold in completely automatic digital operation. With years of production, we’re with advanced machine resources, and a skillful team well-trained to program and run the project with high efficiency and accuracy.